The position of the float must only be adjusted when the needle valve or the float is replaced.

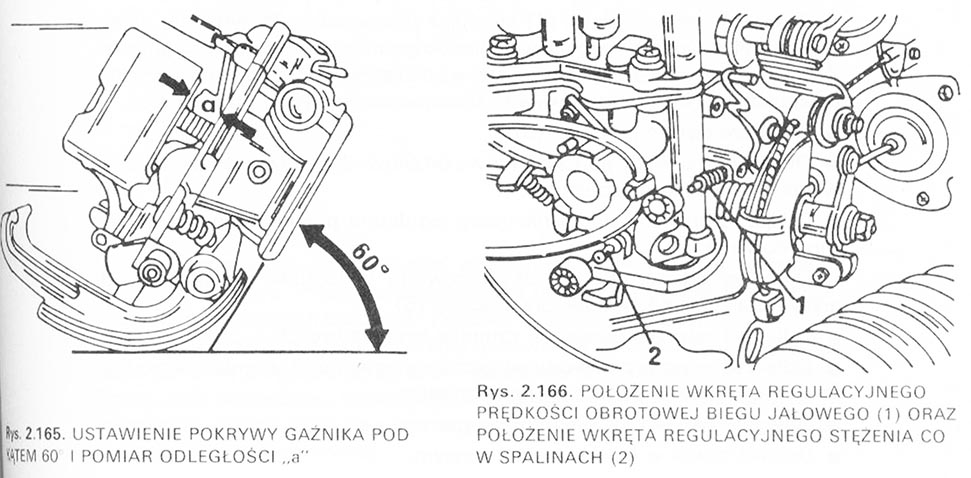

■ Set the carburetor cover to the position shown in the illustration 2.165. The ball of the valve needle sits flexibly in the needle – need caution, so that the ball is not pressed in.

■ Check with a drill bit diameter 9,0 mm dimension “a” shown in the figure 2.165. Permissible deviation ± 1.0 mm. The position of the float can be changed by selecting washers under the valve seat.

Adjusting the idle speed and the concentration of carbon monoxide in the exhaust gas

Idle speed and exhaust gas composition are closely related.

■ Bring the engine to operating temperature.

■ Check, that the start throttle is fully open. Cable ,,suction” should be pushed all the way in.

■ Remove the crankcase breather hose from the port on the air filter. Plug the cable outlet.

■ Adjust the ignition.

■ During adjustment, the radiator fan or the air conditioning unit must not be running.

■ Connect a flue gas analyzer (in cars with catalytic converter, connect to the carbon monoxide test lead located in the engine compartment). The connection should be tight.

■ Measure the speed (tachometer). When it is necessary, adjust with the screw (1, lynx. 2.166) at 900 ± 50 rpm.

■ Measure the CO concentration in the exhaust gas with an analyzer. The concentration of carbon monoxide should be within 1.0 ± 0.5%. When it is necessary, turn the screw (2), until the correct exhaust gas composition is obtained. If the oxide concentration increases after the crankcase breather hose is installed, this is due to an excessive amount of oil vapor in the crankcase.

Testing the idle speed boost system during deceleration

■ Bring the engine to operating temperature.

■ Check, that the start throttle is fully open.

■ Connect the tachometer according to the manufacturer's instructions.

■ Start the engine and increase the speed to 4000 RPM.

■ Release the throttle lever. The rotational speed should decrease slowly to 1800 RPM. Fix yourself at this level for a while, then quickly reduce to idle speed. If it is not so, the cause of the malfunction of the system is most often damage to the throttle actuator, the speed controller or its power supply. Have the parts checked by a specialist workshop.