Adjustment and testing of the KE-Motronic injection system – Audi 80.

The KE-Motronic injection system is installed in the engines 2,0 dm3 of both eight-valve ones, as well as sixteen-valve. The description applies to the 3A engine. A special feature is the blocking of the ignition and injection systems, that is, the operation of both systems is directed from a common control device. In the central control device, information on the instantaneous states of the engine is collected in the form of input signals, then they are processed and sent from the device as output signals controlling the amount of fuel dose, injection duration and optimal ignition point setting.

Idle adjustment and the concentration of carbon monoxide in the exhaust gas.

Special instruments are needed to check and adjust the system. Descriptions of some control and measurement activities are intended to familiarize users with the principles of operation and enable immediate repairs.

■ Start the engine and warm up to operating temperature. Disconnect all electric consumers for checking, including radiator fan motor.

■ Disconnect the air conditioning unit.

■ If injection lines have been replaced or unscrewed, start the engine and increase the RPM several times to 3000 RPM. The engine should be run at idle speed for at least 2 minutes, before starting the adjustment.

■ The exhaust system should be tight, and the lambda probe works fine.

■ Connect the tachometer and analyzer according to the manufacturer's instructions. Samples to determine the concentration of carbon monoxide must be taken from the stub on the left side of the car (viewed from the front of the car).

■ Start the engine and establish idle speed (780…900 rpm or 800…1000 RPM). Switch on the air conditioning unit – the rotational speed should increase by 70 RPM.

■ Check the position of the ignition point with a strobe lamp, which must be connected in accordance with the lamp's instruction manual. The light beam should be directed through the inspection hole in the flywheel housing. A flash point mark will appear in the lamp light.

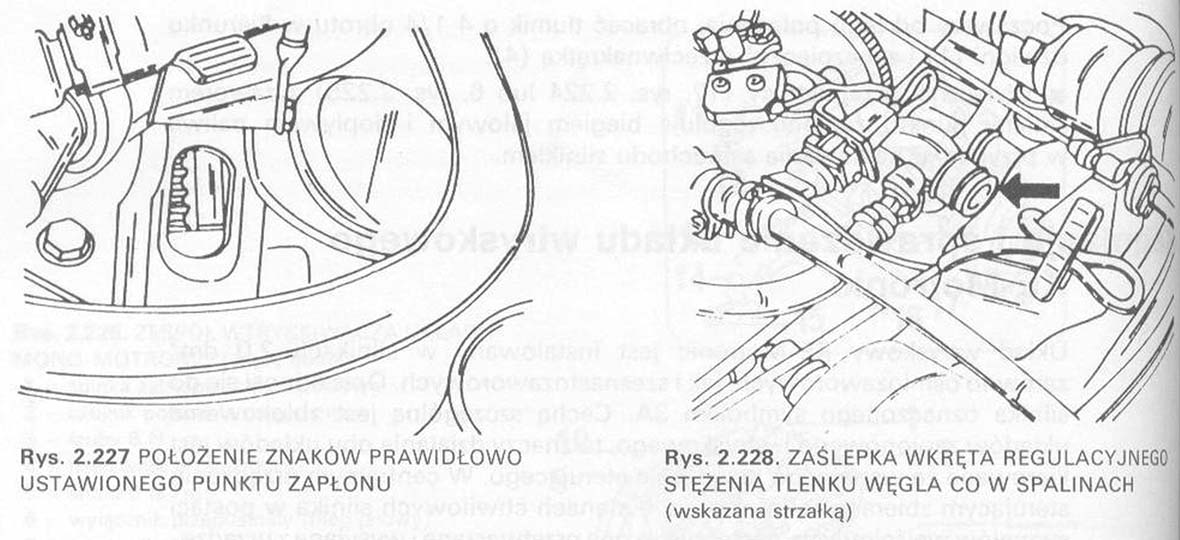

The point should coincide with the mark on the housing as shown in the figure 2.227. If the characters do not match, loosen and turn the ignition device, until the marks match.

■ Increase the engine speed three times to 3000 RPM, then reduce the engine speed to idle.

■ Check the engine speed and the carbon monoxide concentration in the exhaust gas. If the rotational speed and carbon monoxide concentration are different from those recommended, the car should be sent for repair at a service station equipped with devices enabling engine adjustments.

■ The carbon monoxide adjusting screw is secured with a blind plug (lynx. 2.228). Insertion of the plug is possible by drilling a hole with a diameter 2,5 mm. Screw a sheet metal screw with a diameter into the drilled hole 3,0 mm. Pull the head of the screwed in sheet metal screw with pliers and remove the cap. By turning the adjusting screw, the screw can be brought into this position, that the requirement for the concentration of carbon monoxide in the exhaust gas will be met. After completing the adjustment work, plug the adjustment screw hole again.

Work safety regulations – Because the injection and ignition systems are interlocked with each other, the regulations governing work with electric ignition systems must also be observed.