Cell plates (electrodes) are connected into identical sets by means of pole bridges that conduct electricity. There is one set of negative plates and one positive plate in the cell. Because they slide between them, in order to make full use of the inner surfaces of the end plates, one more than the positive plate is added to the set of negative plates, so that the number of working surfaces of both signs is the same. The single plate is constructed in the form of a grid made of lead alloy, into which a mass composed mainly of lead and additives affecting, among others,. to the polarity of the plate. This mass after heat treatment, seasoning and electrochemical treatments becomes the so-called. active mass, taking part together with the electrolyte in the process of collecting and releasing electric energy. In the active mass of the positive plate, the basic component is lead dioxide (PbO2), and in the active mass of the negative plate - lead (Pb) in spongy form. Due to this, that positive plates are subjected to more destructive action than negative ones, they are usually made a bit thicker.

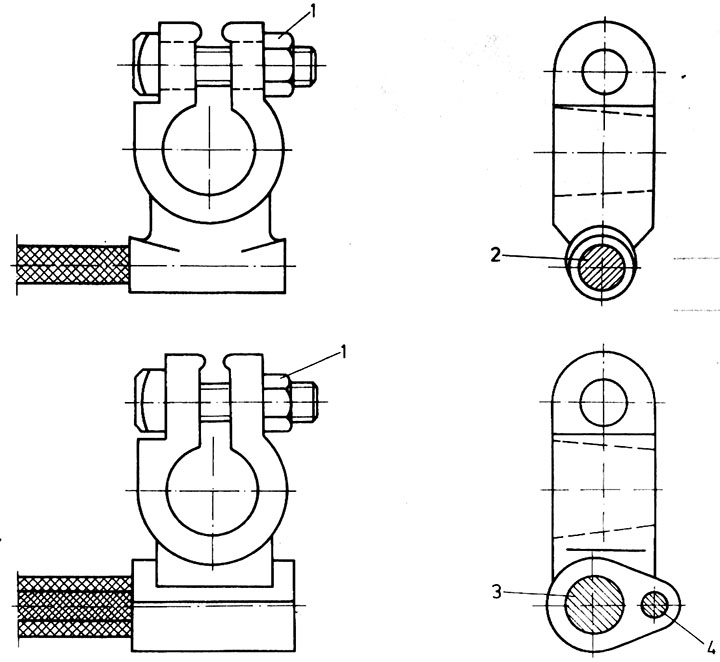

Car battery terminals:

1 - M6 nut; 2 - cable 16-35 mm2; 3 - wire 35 mm2; 4 - wire 6 mm2

Plates in positive and negative sets, separated by separators, placed in the chambers of the vessel (block) battery. Since the nominal voltage of one cell is 2 V, number of cells (and chambers) depends on the required battery voltage. There is them 6 in 12 volt batteries and 3 w 6 – volt. The battery block is divided inside by vertical walls (so-called. bulkheads) on the chambers, which are a separate vessel in themselves. Vertical fins are made on the bottom of each chamber (tracks), on which the plate sets are based, so that a free space remains between the lower edges of the plates and the bottom of the chamber. This is a sedimentation chamber, in which, during normal operation of the battery, active masses flowing from the plates and other impurities are collected. Deposition of them in the chamber under the plates, and not between them prevents internal short circuits in most cases. Arranged in cell chambers (purposes) the sets of plates are combined into a battery. This is a serial connection, i.e. positive pole of one cell (set of positive plates) connects to the negative pole of the adjacent cell (negative plate assembly). Depending on the design of the battery, these connections are made inside or outside the block. In currently produced 12-volt batteries with plastic blocks (mostly polypropylene) intended for passenger cars and vans, the connections between the cells are made inside. In older types of batteries for passenger cars and in batteries with high electrical capacity intended for trucks, ebonite blocks are used, while inter-cell connections are generally made externally. Batteries with plastic blocks are closed from the top, so-called. monolith, tj. one-piece plate, through which the pole terminals are led out (positive and negative) and in which filler holes are made for each cell chamber (hold back). In batteries with an ebonite casing, monolids are generally not used (and if, it is mostly of the superimposed type), and each link has a separate cover, from which the ends connected on top with inter-link connectors protrude. A pouring hole is made in each lid. The lids between each other and between the walls of the block are sealed with asphalt sealant. The mono-hook is connected to the block by welding or gluing. Unlike batteries with separate cell covers, batteries with monolithic lids (monoliths) they are non-detachable.

The filler holes are covered with special plugs. They have holes (mostly labyrinthine) to allow the gases to escape (oxygen and hydrogen) emitted from the cells during charging. Filling holes are used to pour electrolyte into the battery, taking electrolyte samples to measure its density as well as checking and replenishing its level.

Electrolitem is an aqueous solution of chemically pure or battery sulfuric acid with a density in a fully charged battery of 1,28 g/cm³. The electrolyte level should be between 10 do 15 mm above the top edges of the boards or approx 10 mm above the upper edges of the separators, or be between the “min” and ,,max” marked on polypropylene enclosures, indicating the minimum and maximum electrolyte level in the block.

In each link, a punched plastic strip is laid over the plate sets (so-called. protective insert) acting as a damper for electrolyte level fluctuations, that occur while driving the car (the plates should always be immersed in the electrolyte). At the bottom of the filler holes, there are several tens of millimeter long sleeves protecting the electrolyte from spilling when the battery is tilted by an angle not exceeding 45°.

Batteries of the basic series

| rated voltage | Type of execution | Sequence number of the execution type |

| digits (group) | litera (typ) | digit (size) |

| Np.: 6 V, 12 V | Np.: B - Low M - Medium H - High D - Heavy duty | Np.: from 1 do 6 |

| Marking example:

6M3 - 6-volt mid-height battery, third of a kind 6M |

||

Batteries of the additional series

| The number of cells in the battery | Battery type depending on the type of discs | Capacity

rated |

Additional information from the manufacturer regarding the type of separation between the panels, housing type, monolith type, etc. |

| digits (group) | two letters (typ) | digits (size) | litery |

| Np.: 6 for batteries 12 V | Np.: SC, SD, I KNOW, SF | Np.: 34 A h, 45 A h, 60 A h | Np.: D wooden separation, M microporous separation, E – ebonite casing, F – according to WT FIAT, MN – mono-lid put on, MW insertable monolid, MZ – welded monolid |

| Marking example:

6SC34F - a six-cell battery, car, made of type C plates, of rated capacity 34 A h, made in accordance with technical requirements (WT) FIAT. |

|||

14