The intake system, together with the valves and valve slots, fulfills complex and responsible tasks in the engine: supply and distribution to the engine cylinders of fresh cargo, and in the case of carburettor fueling - also preparation of the fuel-air mixture. Moreover, the design of the intake system influences the initial swirling of the charge in the cylinder and the course of the torque characteristics (and therefore the flexibility of the engine). Due to the pulsating nature of the charge flow, the dynamic properties of the intake system are also important. Comprehensive calculations, aimed at assessing the characteristics of the intake system, taking into account all factors important in the operation of the engine, are a difficult and laborious task (and currently only partially possible). In this study, an attempt was made to assess the effect of the volume of the intake system on its flow parameters and the characteristics of carbureted combustion engines.

The intake system, together with the valves and valve slots, fulfills complex and responsible tasks in the engine: supply and distribution to the engine cylinders of fresh cargo, and in the case of carburettor fueling - also preparation of the fuel-air mixture. Moreover, the design of the intake system influences the initial swirling of the charge in the cylinder and the course of the torque characteristics (and therefore the flexibility of the engine). Due to the pulsating nature of the charge flow, the dynamic properties of the intake system are also important. Comprehensive calculations, aimed at assessing the characteristics of the intake system, taking into account all factors important in the operation of the engine, are a difficult and laborious task (and currently only partially possible). In this study, an attempt was made to assess the effect of the volume of the intake system on its flow parameters and the characteristics of carbureted combustion engines.

Volume requirements for engine intake systems

Among the many factors that determine the correct course of the mixture preparation process, the most important - depending on the design of the intake system - are: the speed of the mixture flow and its pressure. There is no information or studies in the literature that would specify the geometric features of the intake system and their impact on the above-mentioned factors. Also, the information on the properties of the flow intake systems of the majority of internal combustion engines operated in Poland is incomplete.

In order to obtain the necessary information about the intake systems of typical internal combustion piston engines, the authors analyzed them and calculated the most characteristic comparative index kd.

Vd - the volume of the engine's intake system measured from the carburetor attachment point (ZI engines) or from the inlet point to the manifold (diesel engines),

Vc - displacement of one cylinder,

k - coefficient resulting from the overlapping of filling phases (k = 1 - engines 2-, 3-, 4-cylindrowe; k = 1,5 - 6 cylinder engines; k — 2 - 8 cylinder engines).

The value of the kd index, for the engines of the Polski Fiat 126p car it is several times lower than for the engines of other vehicles. This is largely due to the design of these engines, the intake manifold channels are an integral part of the engine head. The presence of the intake system geometry should be decided by a deliberate and deliberate compromise. However, it seems, that due to the underestimation of the importance of the volume of the intake system, the existing intake systems do not fulfill their tasks satisfactorily.

The effect of the volume of the intake system on the air flow through the carburetor

The relatively large discrepancy in the characteristic volumetric indicators was the reason for the numerical analysis to assess the air flow through the engine intake system, assuming its different volumes, depending on the angular position of the crankshaft. Calculating the speed of air flow through the intake valve and carburetor throat (resulting from pressure changes) and the mass flow rate of air were made with the following assumptions:

– each cylinder is powered by its own carburetor,

– the temperature in the intake system is equal to the ambient temperature,

– the cylinder is filled with air.

With a small volume of u!inlet line (Vd / Vc = 0,2) there is a variation in the flow rate through the carburetor throat, very close to the flow rate through the valve gap. It follows from the course of the given values, that as the volume of the intake system increases to the value of V / Vc = 1,0 the maximum value of the mass flow rate decreases and moves towards the return of the inner piston. It results from here, that the currently filled cylinder first sucks in the mixture already accumulated in the engine's intake system, and only as the pressure in it is lowered (due to suction into the cylinder) the flow rate through the carburetor throat increases and the intake system is refilled.

From a certain limit value of the intake system volume, there is no return flow of the mixture after the piston has passed internal exhaust. The mixture flowing backwards through the carburetor makes the mixture even richer. It is due to the fact, that the mixture flows through the carburetor (even in the opposite direction) sucks in a certain amount of fuel due to the vacuum generated in the throat. This enriched mixture enters the cylinder on the next fill stroke.

From the point of view of the operating conditions of the carburetor, it is desirable, so that pulsation of air flow through the carburetor is as low as possible. Increasing the ratio of the intake system volume to the cylinder displacement reduces the pulsation of the mixture flow through the carburetor throat and reduces (or even fading away) backflow through the carburetor. This enables better mixture preparation and reduced fuel consumption. It must be noted, that the pulsation of the flow through the carburetor depends first of all (in addition to the factors discussed) on the number of cylinders fed by one carburetor.

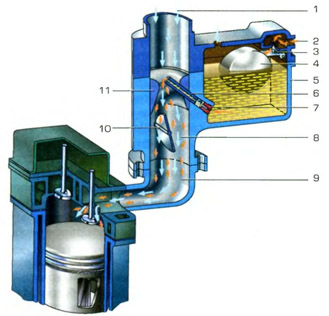

Increasing the volume of the intake system

The presented list of characteristic volumetric indicators and the analysis of air flow through the engine, for different volumes of the intake system, indicates the advisability of increasing the volume of the PF 126p engine intake system. To increase the capacity of the intake system, install an additional metal washer between the cylinder head and the carburetor and connect a pressure-tight vessel to it (with a volume of approx. 0,2 dm8). This modification allows the volume of the engine's intake system to be increased to Vd = 248 cm8 (in the manufacturer's solution Vd = 108 cm3). Then, np. for the 126A1 engine, the reference kd increases from the value 0,33 (standard) do 0,76 (with additional capacity), tj. takes a value similar to that found in other constructions.