Thanks to its simple design and constantly improved manufacturing technology, Glow plugs have become one of the more durable components of diesel engine accessories. Many drivers forget about their existence and do not take into account, that they have a decisive influence on the engine start-up. A defective glow plug can be more trouble than the most severe frost.

Thanks to its simple design and constantly improved manufacturing technology, Glow plugs have become one of the more durable components of diesel engine accessories. Many drivers forget about their existence and do not take into account, that they have a decisive influence on the engine start-up. A defective glow plug can be more trouble than the most severe frost.

Diesel engine pistons, moving down, they suck clean air into the cylinders, which is compressed as it travels back to pressure 3-6 MPa. Thus, air is occupied at the turning point of the piston 1/30-1/60 initial volume and according to the rules of thermodynamics it is heated to a temperature of 700-900 ° C, which is enough, to ignite the fuel injected into the cylinder at that moment.

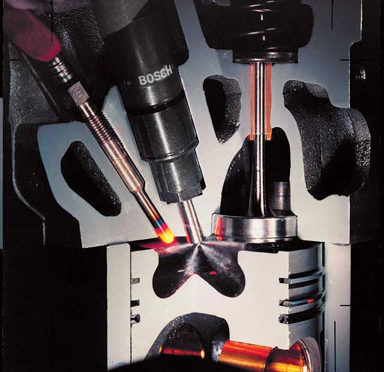

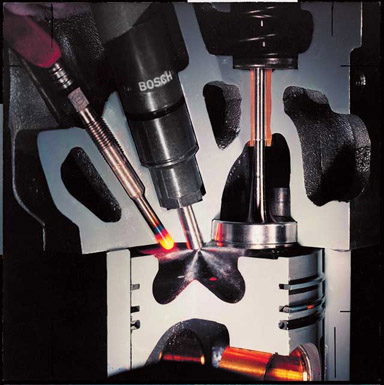

As can be seen from the above description, diesel engines do not need any mixture or spark plugs to initiate combustion, or the rest of the ignition system, known from spark ignition engines. They are, however, difficult to start at low ambient temperatures. To make it easier or even possible to start a cold engine, air flowing into cylinders or already filling their working spaces should be intensively heated. Electric heaters screwed into the combustion chambers from the outside are used for this purpose, colloquially known as glow plugs.

In the operation of the candle (electric heater), The Joule effect of heat generation was used when current flows from the battery through a resistor, which is a spiral heating cable. After switching on the voltage supplying the plug, the temperature of the heating cable increases until, when the power given off to the environment in the form of heat equals the power of the supplied current. If you neglect the slight energy loss in the conductors supplying electricity to the glow plug, to 100% of the supplied electricity is converted into heat. The intensity of heat dissipation by the heating coil depends on the power dissipated on the wire, coming to 60 W, and from the heat transfer surface. Therefore, the heating coil is generally a few turns.

Each engine cylinder has a separate glow plug, screwed tightly into the head. The spark plug heating cable protrudes at the point where the mixture is formed, thus inside the pre-chamber or the swirl chamber (diesel engines with split combustion chambers), possibly directly in the combustion chamber (direct injection diesel engines).

Since the inception of diesel engines, glow plugs have undergone several basic design changes. The once popular bipolar candles with an exposed heating coil are no longer used and can only be found in older cars. On the other hand, single-pole glow plugs with a covered heating spiral have found widespread use, also called pin or bar candles. The heating element here is a closed tube, the correct heating coil is located, constituting a very precisely made part. The precision of the ego-type candle is given as the reason for the long development time of the structure. The basic idea behind the construction of a bar candle was patented as early as a year 1908. However, large-scale production only started in the 60.

Glow plugs